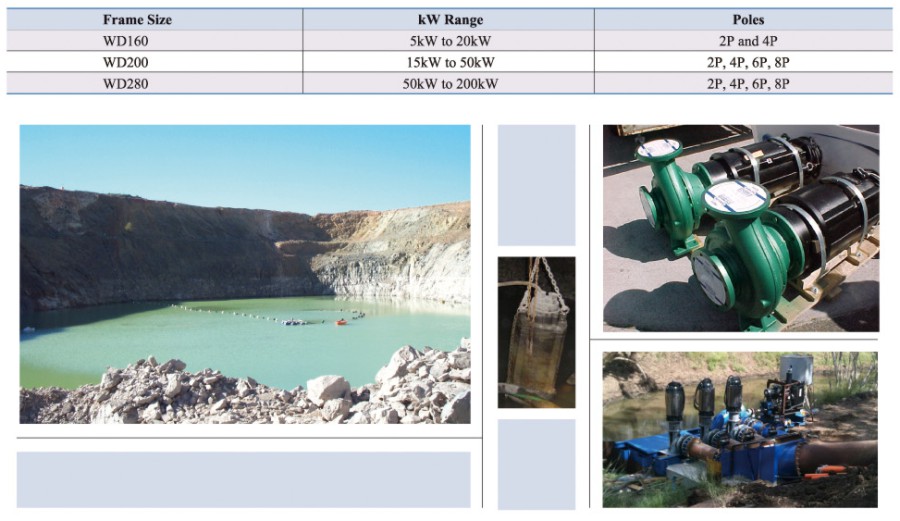

SME – WD Series Motors – for Open Well or Sump Applications Submerged or not Submerged, Cast Iron, Steel, or Stainless Steel Construction

SME has many years experience in the manufacture of submersible motors and the WD series of motors have been designed for the toughest jobs to ensure reliability and a long service life. When conditions are extreme and performance is critical these motors deliver the quality and durability required.

WD motors are designed for continuous operation in sludge, effluent, slurry, and other liquids – to a submergence of 10 metres, in an open well, a river bank, a tailings pond, or a sump. The motors are air filled, with a separate oil filled seal chamber to ensure robust sealing of the drive shaft. The WD Series motors can also be supplied with a large range of sealing options to ensure the motor is suitable for the most extreme conditions from a combination of lip seals, and/or mechanical seals, to complex cartridge seal arrangements.

If the motors are going to be continuously submerged they will rely on the liquid they are submerged in for cooling. If they are not going to be submerged continuously – or only intermittently — they are designed with a water jacket for cooling and water is usually bled from the pump through the water jacket.

These IP68 motors have been used in both vertical and horizontal applications driving a diverse range of pumps in many unique applications. The Motors can be supplied with an extensive array of flange and shaft dimensions to ensure the motors can be matched to a large range of different pumps. The motors can also be supplied with standard IEC and NEMA flange and shaft dimensions.

The motors are very robust and designed to take the physical abuse on a typical mine site. They can tolerate overloads, and a lack of cooling. They can maintain full load operation for 15 minutes with no external cooling. These motors offer a robust alternative to other units that suffer from shorter operating lives – with no changes to the existing Wet end performance.

These motors are fitted with moisture detection probes and PT100, or themiistor, thermal protection — as standard – and provided these are properly connected and set to give advance warning of problems these motors will give many years of reliable service in extreme applications.